If you’re gearing up for increased business or have long production runs, a Gear Pump Preformer will provide you with continuous production capability for your preforming. It will also reduce your machine set-up time and negate the need to pre-heat rubber on a two-roll mill which is required when using ram preformer. A Ram Preformer is the preferred solution for batch production.

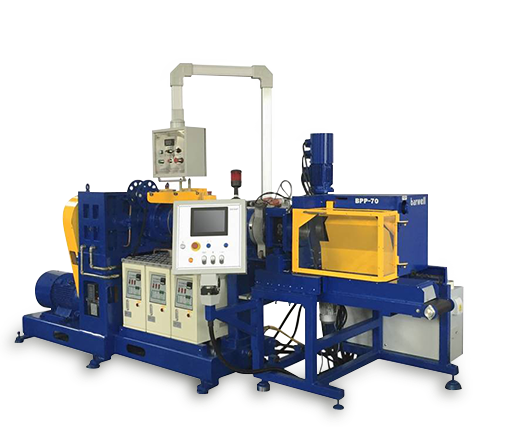

The Barwell Gear Pump Preformer is a fully automated and highly advanced screw extruder with integral gear pump, specifically designed to provide high levels of control and processing flexibility for the continuous preforming or extrusion of almost any form of rubber compound. It combines three key elements, the plasticizing properties of a cold feed screw extruder, the volumetric flow control properties of a gear pump and the proven Barwell cutter system.

How does the Barwell Gear Pump work?

Material is delivered to the gear pump by a screw extruder which masticates the material prior to entry. The masticated material is pulled into the pump by intermeshing herrigibone gear teeth at a constant rate, irrespective of screw rotation speed, ensuring the gear pump cavity remains full. Minimal shear is generated in the gear pump so increases in material temperature are minimal – important when processing temperature sensitive materials.

The material is then compressed at the outlet point at a constant rate enabling precise control over dimensional stability. The constant rpm of the gear pump and monitoring and regulation of inlet pressure help overcome extruder pulsing. This assists during strip feed change-over. The gear pump is independently driven but controls the screw rpm by means of inlet pressure monitoring.

Without a gear pump the pressure build up and extrusion uniformity is directly influenced by the screw rotation and compound variations. With a gear pump these variations are monitored at the pump inlet and adjustments made automatically to maintain constant output flow.

Whilst the pressure at the inlet varies (due to material changes, feed variation etc.), the pressure at the outlet of the gear pump remains constant ensuring improved extrusion quality and control of extrudate dimensions.

By keeping the gear pump rpm constant, it is possible to influence the plasticising effect on materials by changing the screw rpm. Increasing the screw rpm increases the inlet pressure and also the compound temperature as greater mastication is achieved during the dwell time in the extruder barrel. This has significant advantages when processing difficult materials that need additional mastication to achieve output requirements.

Material flow through the gear pump is generally linear and dependent on pump rotation speed. Increasing rpm will automatically adjust the screw feed to maintain inlet pressure and cavity fill. This is not influenced by varying material characteristics.